Requirements and Specifications

Hazard Identification Risk Assessment and Control

A survey must be undertaken across all KPC mining and infrastructure leases in order to:

- identify all areas considered to be confined spaces

- determine the signage requirements for denoting the confined space

- document the above

Conducting a Survey

The process of identifying all confined spaces within KPC will need to be carried out by suitably trained and knowledgeable personnel regarding confined spaces. The definition of a confined space must be clearly understood to ensure all confined spaces are identified.

A confined space is an enclose or partially enclosed space that is at atmospheric pressure during occupancy and is not intended or designed primarily as a place of work, and

(a) is liable at any time to

1. have an atmosphere which contains potentially harmful levels of contaminant;

2. have an oxygen deficiency or excess; or

3. cause engulfment; and

(b) could have restricted means for entry and exit

Each work area must be systematically surveyed for confined spaces. Some examples of methods for identifying confined spaces are:

- physically assessing the work area,

- reviewing existing confined space entry permits, or

- group review

Create a register of all identified confined spaces this is a record of specific information on the identified confined space as outlined below:

- Register number

- Type of confined space (eg tank, truck)

- What the confined space contains

- Size of the confined space

- Volume of confined space

- Type of equipment

- Location of confined space

- Unit number (if a vehicle or equipment)

- Type of signage/labelling

- Is labelling complete

The register may record an entire companies confined spaces, a division of a company or a specific work area, the register should be easily accessed for relevant employees. An example of a confined space register is provided in appendix A. All confined spaces must be subject to a risk assessment prior to permit of entry in order to determine, as a minimum:

- oxygen levels, contaminants, temperature extremes, and concentrations of flammable sub stances

- isolation procedures for contaminants and other energy sources

- the requirement for breathing apparatus

- the development of rescue plans and the required equipment

- all other aspects of safe operation including:

* access / egress requirements

* hazards

Confined Space Entry Risk Assessment

When conducting a risk assessment the detail will depend on the type of confined space and the task carried out. Suitable methods for performing the risk assessment are Job Safety Analysis and the confined space entry permit. In the case of hazardous work a detailed risk assessment will need to be conducted to ensure all risks are identified and control methods put in place.

The risk assessment will need to be completed by a competent person or persons before work associated with the confined space is carried out. In some cases using a work team will develop a more comprehensive assessment. If using a team to conduct the risk assessment ensure the personnel involved

- have knowledge of the particular confined space under assessment

- have knowledge of the work methods which to be used during the job

- understand confined space entry practices and are

- competent to carry out risk assessments

The following risk controls need to be assessed prior to entering the confined space.

For information on carrying out a risk assessment refer to Hazard Identification, Risk Assessment & Control Code of Practice

Any risk identified as having a potential to cause a fatal incident must be controlled before entry into a confined space is authorised.

Risk Control

Risk control is the process of determining and implementing an appropriate measure to control risks. The main aim is to eliminate where possible any risk associated with work in the confined space. If the risk cannot be eliminated then controls will need to be put in place which makes the risk acceptable to continue the work. Risk elimination or reduction is generally achieved by a combination of controls. The risk control categories listed below provide guidance on some control measures available.

Elimination

Complete elimination of the need to enter the confined space should be the first consideration, as safety is best secured by avoiding the need to enter a confined space. For example, to eliminate the need to enter:

- Can a tank be flushed to remove any possible contaminants

- Can an object dropped in to a tank, sump or other vessel from outside the vessel be retrieved using a hook or long handled clasp

- Can the inside of a confined space be inspected using a video camera

- Can a reading device located inside the space be relocated to the outside so as to eliminate the need for future entry?

The adoption of purchasing policies that take account of safety when buying plant can often eliminate risks.

Substitution

If elimination of the need to enter the confined space is not practicable, consideration could be given to substitution of processes or substances to reduce the risk, for example:

- Can a surface in the tank be scraped rather than dissolved with chemicals?

- Can a non flammable solvent be used in place of a flammable solvent?

- Can a detergent be used in place of a chlorinated solvent for cleaning?

- Can paint be applied by brush rather than aerosol application?

Isolation and Engineering Control

Isolation in relation to confined spaces usually involves engineering controls such as the positive isolation of plant or service purging or ventilation and the use of intrinsically safe plant where a flammable atmosphere exists or may arise. Modifying the design of a piece of plant which incudes a confined space may result in a change to the way the space works or operates. If the design is modified, the process of hazard identification and risk assessment should be repeated.

Administrative Control

Administrative controls involve the use of safe systems of work to control the risk, such as safe work procedures. The permit system is an administrative process used to manage the hazards associated with confined spaces.

Personal Protective Equipment

Where personal protective equipment is used to control risk, it must be selected, maintained and used appropriately.

Review of Control Measures

Control measures should be reviewed and improved, maintained, extended or replaced as necessary to ensure adequate control. Reviews should take place at regular intervals or as indicated by the risk assessment record.

Selection, Training, Competency and Authorisation

All personnel conducting risk assessments on confined spaces must:

- have completed confined space training

- be assessed as competent to perform the risk assessment

The training and competency assessment system shall ensure:

• competency standards for the confined space entry team including the inspection, use, and maintenance of:

* monitoring equipment

* breathing apparatus and confined space entry equipment

* ventilation equipment

* rescue equipment

• competency standards for the confined space entry permit issuer

• training and formal competency assessments for the above personnel

• the recording of all training undertaken and results of competency assessments

• 12 monthly re-assessment of competencies

Confined Space Training Requirements

Appropriate training is extremely important to working safely in confined spaces. All personnel who are part of the confined space entry team should be trained and competent in the following requirements:

• recognition and identification of potential hazards associated with the confined space that will be entered

• evaluation and control procedures for the identified or potential hazards

• all personal protective equipment (eg. Respirators) that the worker will be using while in the confined space

• all procedures for entering the confined space

• procedures to follow in the event of a situation developing that could present additional risk to the worker or an emergency

• the specific work to be done in a confined space

In addition workers with standby responsibilities will need to be competent in ventilation equipment, harnesses and air quality monitors. Workers with emergency rescue responsibilities will need additional specialized training. All confined space training should include some hands on training with the safety equipment including the personal protective equipment and safety harnesses. Rescue procedures should be practiced frequently so there is a high level of competence. Employers should keep records of all confined spaces training including refresher courses. The selection and placement evaluation process shall ensure personnel required to operate in, or perform work within confined spaces meet defined criteria for medical fitness and health.

Medical Fitness & Health

As part of the selection process (new employees or employees transferring to a dissimilar job) medical certification of fitness must be obtained prior to an applicant or transferee being considered suitable for the job. A health assessment for relevant employees shall determine their fitness and safety to enter and work within confined spaces and/or potentially hazardous atmospheres and to undertake required training. The assessment of fitness to enter and work within confined spaces/potentially hazardous atmospheres will need to include as a minimum:

- Annual employee self assessment (prior to refresher training)

- Trainer observations (at time of refresher training)

- Medical practitioner assessment as required

Referral to a medical practitioner would generally occur if:

- The employee elects to attend as part of the self assessment process

- Trainer’s observations indicate the need for further medical assessment

- At any other time the Line Manager, with valid cause, considers medical assessment justified.

Fitness to enter a confined space and/or hazardous atmosphere generally requires:

- Lack of claustrophobia (fear of tight or enclosed spaces)

- Ability to wear a SCBA full-face mask and to obtain an adequate seal

- Ability to wear a harness and lifeline

- Adequate communication capabilities (speech, hearing and vision) for a security or rescue role

- Muscle, joint and spine fitness sufficient to wear SCBA equipment, enter/exit manholes, pipes and tight or enclosed spaces and climb ladders etc

- Good general fitness ie. No chest pain, palpitations, faintness, dizziness or undue shortness of breath on exertion

- No medical condition which might lead to sudden loss of consciousness or an inability to respond eg. Epilepsy, diabetes, fainting/blackouts/turns and certain medications. Training should be provided to only those employees confirmed to be fit.

Communication and Awareness

Changes to confined spaces and related procedures and/or rescue plans must be:

- documented and / or documents updated

- incorporated in rescue plans

- communicated to personnel who may be affected

Confined spaces must be identified and signs erected at the entry points indicating that a permit is required prior to entry.

Signage

All confined spaces need to be identified, placed on a register and labelled as a confined space which signifies that a permit is required prior to entry. Ensure that personnel who are identifying the confined spaces are competent in understanding the definition of what a confined space is. The confined space sign will need to be placed in a position that is clearly identified prior to work being carried out. For example, place a confined space entry sign at the base of a tank to prevent the need to climb all the way to the top access and then finding out it is a confined space which requires a permit prior to entry.

The following are examples of some confined spaces that can be found at mine sites:

- Storage tanks • Degreasing pits

- Process vessels • Wells

- Boilers • Excavation holes

- Sumps • Refrigeration units

- Pipes • Tanks or vats

Awareness information and/or instruction must be provided on a regular basis to personnel who perform work in confined spaces, and must include topics on:

- confined space hazards

- permit requirements

- confined space entry equipment and procedures

Awareness Information

When determining the level and type of awareness information that needs to be provided to personnel take into account the frequency and type of confined space personnel are required to enter. When discussing confined space hazards try and apply them to the type of work personnel are exposed to, make the information relevant to the jobs performed. It maybe a good idea to raise awareness at the start of a shift when a confined space entry job is required or when confined space work is coming up in the near future. Confined spaces can become far more hazardous when other hazardous tasks are introduced to the space, such as hot work, electrical work, or painting. The general hazards that occur in confined spaces are:

• Oxygen deficient atmosphere

• Engulfment by contaminants

• Explosion or fire

• Exposure to toxic atmosphere

• Electrocution (power tools being used)

Raise awareness and understanding of confined space entry procedures that are specific to certain hazards or jobs, explain the importance of these procedures and why they have been developed. Discuss the safe use of confined space equipment relevant to the job being carried out and the impact of personnel not being competent to use the equipment. Permit requirements should be raised including topics covering,

• atmospheric testing,

• permit issuer responsibilities,

• confined space entry personnel responsibilities such as sign in and out,

• duration of the permit,

• special precautions listed on the permit

Design, Purchase, Fabrication, Installation and Commissioning

Purchasing specifications must be developed for all confined space entry equipment including:

- monitoring equipment

- breathing apparatus

- ventilation equipment

- rescue equipment

Extraction systems for use in confined spaces must be fit for purpose and that all materials used must withstand any corrosive or flammable condition to which they may be exposed. Purchasing specifications are established to standardise equipment and ensure any specific requirements are complied with.

This ensures the compatibility of equipment and that it meets required standards. Refer to the confined space equipment register to ensure all breathing apparatus, monitoring, ventilation, and rescue equipment meets the purchasing specifications. When purchasing new equipment ensure that it meets specifications outlined. Prior to purchasing an extraction system, review existing confined spaces and potential hazards, make sure that the system will be suitable for the potential materials it will need to withstand.

Work Method and Condition Control

Entry to a confined space must only be allowed after written approval, in the form of a permit. The permitting process must include the following elements:

• a risk assessment must be performed on the confined space entry

• all persons required to work in a confined space must be informed of the hazards and sign the permit prior to entry

• the standby person must be informed of the hazards and the emergency communication requirements

Confined Space Entry Permit

An Entry Permit is an administrative tool used to document the completion of a hazard assessment for each confined space entry. Someone fully trained and experienced in confined space work should complete the Entry Permit. Before entering a confined space, an entry permit should be written. It should contain at least the following information:

- The length of time the permit is valid for.

- The name(s) of the worker(s) that will enter the confined space.

- The name(s) of the attendant(s) (safety watch) and/or supervisor.

- The location of the confined space.

- The work that is to be done in the confined space.

- The date and time of entry into the confined space

- The details of any atmospheric testing done of the confined space – when, where, results, date monitoring equipment was last calibrated. Ideally, calibration would be done just before each use. If this is not possible, follow the equipment manufacturers guidelines for frequency of calibration.

- The use of mechanical ventilation and other protective equipment needed and any other precautions that will be followed by every worker who is going to enter the confined space.

- The protective equipment and emergency equipment to be used by any person who takes part in a rescue or responds to other emergency situations in the confined space

- A signature of a worker who did the confined space testing.

The signature on the permit would indicate that adequate precautions are being taken to control the anticipated hazards. The entry permit should be posted at the confined space and remain so until the work is completed. The employer should keep a copy of the completed permit on file. See appendix C for an example of a confined space entry permit. The standby person will have no other duties and must be positioned outside the confined space entry point at all times while personnel are within the space.

Standby Duties

The Standby person is posted outside the confined space and continuously monitors the workers inside the confined space. The standby person has the following duties:

- understands the nature of the hazards that may be found inside the particular confined space and can recognise signs, symptoms and behavioural effects that workers in confined space could experience

- monitors the confined space and surrounding area and is on the look out for hazards

- remains outside the confined space and does no other work which may interfere with their primary duty of monitoring the workers inside the confined space

- maintains constant communication with the workers in the confined space

- orders the immediate evacuation if a potential hazard, not already controlled is detected

- calls for emergency assistance immediately if an emergency develops

- is immediately available to provide no-entry emergency assistance when needed

Ventilation must be adequate for the task being performed within the confined space.

Ventilation of a confined space by natural, force or mechanical means, may be necessary to establish and maintain a safe atmosphere. Ventilation should be continued throughout the period of occupancy. The method and equipment chosen for ventilating will be dependent upon factors such as the size of the confined space openings, the gases to be exhausted (i.e. whether they are flammable), and the source of make up air.

- If the confined space has sufficient openings then natural ventilation maybe adequate but in most cases mechanical ventilation is likely to be needed.

- Air should be introduced in a way which will ensure effective circulation throughout the confined space, taking into account the configuration of the space, the position of the openings and the properties of the pollutants.

- During operations likely to generate contaminants, mechanical ventilation equipment may not be adequate or sufficiently reliable to maintain a safe oxygen level.

Where the maintenance of a safe oxygen level in a confined space is dependant on mechanical ventilation equipment, the equipment should:

- be continuously monitored while the confined space is occupied, and

- have the controls (including remote power supply) clearly identified and tagged to guard against unauthorised interference.

Thoroughly ventilate the space with air to achieve normal atmosphere when ever possible – never purge with oxygen.

Specific Safe Work Procedures must be developed for work, which are more hazardous when carried out in a confined space. These activities would include hot work (cutting and welding); chemical cleaning; steam cleaning; and, abrasive blasting.

Hazardous Tasks

Some work when performed in a confined space can create a higher risk than is normally experienced, in this case specific precautions need to be observed to make sure the confined space remains safe to work in.

When working within confined spaces on dredges the following shall be considered:

• Kepmen555-Decree of Mines Article 272 (compartment inspection methods)

For a copy of Kep/Men/555 – Decree of mines article 272 refer to appendix F

Maintenance

All fall protection, rescue, ventilation and monitoring equipment used for confined space entry must be included in a maintenance program which includes:

- schedules for conducting maintenance or calibrations

- requirements that maintenance is undertaken in accordance with manufacturers specifications

- the use of manufacturers or approved compatible parts

- the recording of all maintenance work conducted

Maintenance Program

Establishing a maintenance program for all confined space equipment is important, it ensures that equipment is fit for purpose when required. Maintenance includes visual checks, inspections, testing of equipment, preventative maintenance and remedial work. Repair and maintenance programs should specify:

- Where servicing is required

- What components require servicing

- The type of the servicing required

- The frequency of servicing

- Who is responsible for repair & maintenance programs and

- How will defects be corrected

Steps to Implementing a Maintenance Program

Emergency Controls

A specific rescue plan for each type of confined space entry must be in place and rescue equipment available before any entry to confined spaces takes place.

Emergency planning for confined spaces provides a safety net in the event control measures fail. This failure could result, for example, through equipment breakdown or an unplanned event. All employees who may be involved in any way with rescues from a confined space should be made aware that rescue plans are to be followed at all times. Planning is the key to effective emergency and rescue response. As part of the risk assessment process, emergency rescue and first aid requirements must be taken into account. Plans and procedures appropriate to the types of situations that may arise from work in confined space should be put in place using the information from the risk assessment.

Consideration should be given to the different types of emergency and rescue scenarios that might arise. These include where:

• Employees are uninjured and evacuate them selves

• Employees are injured but still capable of self-evacuation

• Entry is required to provide treatment

• Employees are assisted to evacuate by persons remaining outside the space

• Emergency entry is required in order to evaluate employees

Emergency rescue plans should consider existing emergency, rescue and medical facilities (i.e. Swaga Bara Clinic), and the outcome of the risk assessment and the geographical location of the confined space in relation to emergency, rescue and first aid facilities. Response time is a critical factor in confined space emergencies, therefore the time it would take for emergency personnel to respond should be carefully considered.

Emergency rescue plans should specify the first aid training competencies required by employees (for example, a fist aid qualification that includes cardio-pulmonary resuscitation), In determining what first aid facilities and first aider training is required, the supervisor should consider the following factors:

• Size and layout of the workplace (eg. Distance an injured person has to be transported to medical facility);

• The number and distribution of employees including arrangements such as shift work, over time etc

• Nature of hazards and the severity of the risk

Potential problems with openings for entry and exit size should be identified and assessed during the hazard identification and risk assessment process, and be addressed in the development of emergency and rescue procedures. Where openings are found to be inadequate the size of the openings should be increased where ever practicable. If it is not practical to alter the openings or remove the obstruction, then alternative safe means of entry and exit need to be provided. Suitable rescue equipment must be maintained and available for the range of recovery methods identified in the rescue plans.

Rescue equipment may include breathing apparatus, lifelines and lifting equipment. The appropriate equipment will vary depending on the type of confined space, the risks involved and how persons in the space will be rescued. Assess all known possible rescue scenarios and review the rescue plans. Check that the required equipment is available and competent persons are able to operate it.

The removal of trapped, injured or unconscious persons from confined spaces is extremely difficult. The use of lifting equipment such as a lifting tripod or davits and safety harness should be considered. The rescue procedure should specify what precautions are to be taken if a rescuer has to enter the confined space. Where limitations on entry have been specified, for example, where the atmosphere in the confined space is oxygen deficient, these limitations may also apply to entry for the purposes of rescue. The procedures should cover the need for rescuers to take appropriate precautions.

Monitoring, Inspections and Audits

Inspection of all ventilation and confined space entry equipment must be in accordance with manufacturer’s recommendations, and results recorded.

What to Inspect

Refer to the confined space equipment register (not the confined space register), all items on the register will need to be inspected such as;

• Mechanical ventilation • Breathing apparatus

• Atmospheric monitors • Air line

• Ropes • Communication method (radio)

Inspection Checklist

An inspection checklist should be based on the manufacturer’s specifications and any site operation experience (frequency is generally no less than 6 months). The inspection checklists should include items such as:

• Physical damage • Deterioration

• Wear • Identification markings

• Corrosion/ erosion • Labelling (safety instructions)

Inspection System

Check that the inspection system covers and maintains a record of the following:

- Specific equipment identification • Repairs required and completed

- Persons authorised to conduct inspections • Means of identifying the currency of the equipment

- Specific inspection checklists • Required inspection time frames

- Completed inspections • Persons authorised to carryout repairs

- Faults found

Planned Task Observations and PRINASA’s must be performed for the purposes of measuring compliance to:

• specific safe work procedures

• compliance to permit requirements

• status of rescue plan and equipment

Prima Nirbhaya Advance Safety Auditing Program (PRINASA) is a program designed to assist management to be able to accurately audit the work practices of their employees in the workplace. Staff are expected to conduct an audit on safe work practices in work areas while encouraging employees to follow and if necessary improve those practices.

The frequency that work in confined spaces is required will influence the need to develop an observation schedule or a process for ensuring adhoc confined space entries are observed. Planned Task Observations are applied to an entire process and may be used to obvserve the compliance to a safe work procedure for a hazardous task such as performing hot work.

Reporting Assessment and Corrective Actions

Processes must be in place for the reporting, assessment , and correction of hazards identified with confined space entry equipment or procedures and must address:

• actions required to stand down unsafe equipment or stop work

• the recording of actions taken to correct the hazard or defect.

Identifying hazards or defects

Hazards or defects maybe identified on confined space entry equipment when performing inspections, carrying out maintenance or using equipment. With the understanding that hazards or defects can be identified at various times and locations a system needs to be developed which can ensure these can be reported and assessed accurately.

Reporting the hazard or defect

All persons are required to report any hazard or defect they find, appropriate reports for collecting defect information can be:

- hazard report

- maintenance report

- inspection checklist

If the defect renders the equipment unsafe, it must be appropriately isolated as soon as possible. This includes the requirement to place an out of service tag on the equipment to ensure it is not used until the hazard or defect has been fixed. If the full implications of the defect are unknown, then seek advice from your immediate

supervisor. If the supervisor is advised of a defect, they should check that defect has been appropriately tagged and isolated. Then decide on further action

Assessing and Action

The hazard or defect needs to be assessed by a competent person to decide if the equipment is to be stood down, destroyed or actions taken to correct the problem. A process will need to be developed for standing down or destroying equipment, Australian Standards or the manufacturer may have recommendations for standing down or destroying equipment. The process developed for standing down or destroying equipment must:

- Ensure the equipment is removed from the register if destroyed

- Prevent the equipment from being used again

- Detail requirements for destroying equipment.

The process developed for correcting the problem must ensure:

- It is recorded in maintenance records

- Follows manufacturers or best practice requirements

- Is completed by a competent person

- Is certified for use by a competent person prior to being used again

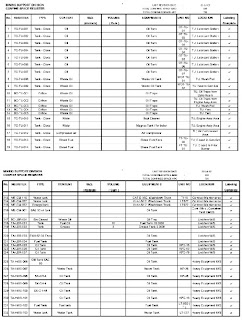

Appendix A

Appendix A – Example Confined Space Register

Appendix C – Example Emergency Rescue Plan

Appendix D – Hot Work Hazard Control

PURPOSE: To identify the major hazards involved in performing hot work within a confined space and to list controls to be considered to manage these hazards.

SCOPE: This applies to all hot work performed in confined spaces within KPC mining and infrastructure leases.

Appendix E – CSE Roles and Responsibilities

Post Views: 489