Drilling

Drilling is common to the winning of rock, coal and clay. The main hazards associated with drilling are :

- Falls from the edge of a bench

- Dust created during the drilling operations

- Noise

- Entrapment in or being struck by a moving part of the drilling equipment.

Risk assessment.

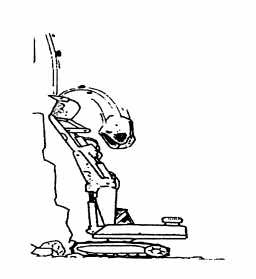

Falls from the edge of a bench

While the primary hazard is that of the driller falling over the edge of a working or abandoned bench the risk of minerals or materials falling onto workers at the foot of the face should not be overlooked.

A face and bench is a necessary part of a working quarry and therefore it is not possible to remove the hazards associated with them.

While others may need to work at or near the edge of a working bench the person most at risk during the drilling operation is the driller. Others such as the manager of the mine or maintenance personnel, may approach the bench edge during the drilling operation in the event of a break down of the drilling equipment.

Clearly people are only at risk when they approach edge of the bench. In normal circumstances there is no need for anyone to be so close to the bench edge as to be liable to fall over it.

However anyone working within say three metres of the edge would be liable to fall over it should they trip or accidentally slip while carrying out their work and might be considered at high risk.

The highest risk will occur during the drilling of the first line of holes parallel with the working edge of the bench. Subsequent parallel lines of holes should not give rise to such a high-risk of falling off the edge of the bench.

A number of control measures can be taken and the first is to ensure that the equipment is suitable for the job and that the person in charge of the drilling machine is competent to carry out the drilling operation; part of the training should include instructions to always face towards the open edge of the bench so that any inadvertent backward step is away from the edge.

One of the measures that can be taken to reduce the risk off the edge of the bench is to provide suitable portable rail fencing which can be erected between the drilling operations and the edge of the bench. Another is to attach a safety line to the drilling rig and provide a harness for the driller to wear.

Another is to restrict access to the area to all persons except those necessary for the drilling operation.

Dust from the drilling operation

The hazard is the inhalation of dust which is created during the drilling operation. While it is not presently possible to totally remove the hazard properly applied control measures can substantially reduce the risk.

The person primarily at risk is the drill operator.

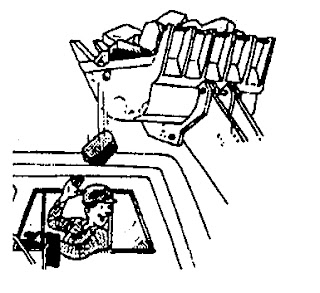

Control measures vary from using water during the drilling operation to the provision of local exhaust ventilation which removes the dust from the head of the hole to a dust collection unit to the provision of a ventilated cabin provided for the operator. The most effective of these precautions is the provision of a control cabin on the drilling rig provided with a suitable ventilation system fitted with a dust filter to remove harmful dust and maintain the dust level within the cabin to below acceptable control levels. Any ventilation equipment should periodically be examined to ensure that it is maintained to its design standard.

Noise

Drilling operations give rise to harmful levels of noise. It is created by both drilling the hole and the operation of the drill rig itself.

It is impractical to remove the hazard at the hole but new generations of drill rig should be quieter by virtue of its design. The noise created is harmful to anyone who is within a zone around the drilling machine at which the noise level is above that considered to be safe for persons to work without having to use control measures.

The noise levels around drilling equipment should be measured and the risk assessed. Unless control measures are in place no-one, except those necessary for the work in hand, should be allowed inside the designated noisy area. In most cases this will be the drill operator.

The risk is highest at older machines. Newer large drilling machines are provided with sound insulated operating cabins which control the noise level within the cabins to acceptable levels.

Other control measures will include training operators and providing them with ear protection, although the latter should only be seen as an interim precaution until a permanent solution can be found.

The risk is very high when no control measures are provided. However if full measures are provided the risk will be low. Entrapment in or being struck by a moving and revolving part of the drilling equipment.

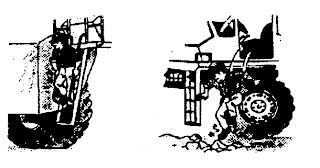

There may be a number of hazards, principally those of moving the drilling rig around the site, traps between reciprocating and fixed parts of the rig and revolving parts such as the drill rods and bit.

The primary hazards associated with the movement of equipment on site and dangerous parts of the drilling rig are an integral part of operating a mine. Those most at risk will be persons having need to move and operate the drilling rig.

The risk of an accident occurring will be low if the dangerous parts of the equipment are properly guarded, operators are well trained and supervised and only those essential to the work are involved in the activities.

However, the risk of an accident will be high if the dangerous parts are exposed and the operators poorly trained and supervised.

Explosives

Explosives by virtue of their nature have the potential for the most serious and catastrophic accidents in the mining industry yet the way they are used is an excellent example of how risk assessment is properly applied. For example no one would allow any person to use explosives with out first having been properly trained in its handling and use.

Increasingly use of explosives is specialist work. Planning for a round of shots is necessary to ensure that the face is properly surveyed, holes correctly drilled, direction logged, the weight of explosive suitable for good fragmentation and the continuity of the initiator are but a few of the steps necessary to ensure its safe use.

Poorly designed shots can result in misfires, early ignition and flying rock. The more sophisticated type of explosive demands properly trained persons to carry out the blast design, charge and fire a round of explosives.

If within a company there is no competent person to do this work competent contractors should be engaged to carry it out.

Face stability

Face instability gives rise to rock falls or slides.

Face instability can arise because of adverse geological faulting or poor work methods.

Those at greatest risk will be face workers engaged in loading material and driving vehicles.

Before any loading takes place the face must be examined and remedial measures taken to make it safe if there is any doubt that a collapse could take place. The working of the face should be in a direction that has taken into account the geology such that the face and quarry sides remain stable.

Particular care must be taken to ensure that the working face at a sand and gravel mine is in proportion to the height of the loader in use.

Loading

The main hazard associated with loading is rock falling on to the driver, plant toppling over due to uneven ground, failure of hydraulic systems, fires and falls while gaining access to operating cabins. Electrocution, and failure of wire ropes are added hazards with some dragline equipment.

Good access must be provided to operators cabins which should be of suitable strength to protect the driver in the event of rock falling against the cab or if the vehicle rolls over.

In addition it is necessary to ensure that the electrical supply to draglines is properly installed with adequate earth continuity and earth leakage protection. Also all wire ropes should the suitable for the work under taken and be examined periodically.

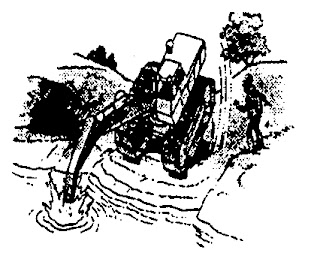

Added risks at sand and gravel mines is the danger of the loaders toppling over if not on secure ground. It is absolutely necessary to ensure that they are positioned sufficiently away from the face edge so that they are not liable to topple into workings.

There is the danger of drowning at sand and gravel pits and suitable precautions must be taken in the form of training and provision and use of rescue equipment.

While the people at work are at most risk, ramblers and trespassers should be included in the risk assessment.

Hydraulic mining

Associated with mining for clay is the danger of using large quantities of water at pressure. Those persons at risk are the operators and any other person who might move in front of the water monitors.

The risk of injuries can be greatly reduced by limiting access to the area to only those necessary for controlling the operations, and implementing a system of work such that the pumping and water supply is isolated when person’s are carrying out maintenance or extending the system.

Wet working

There are particular hazards associated with winning minerals in water laden strata and in its storage and use in lagoons.

They are stability of the working face, stability of machinery, collapse of lagoon walls and drowning. Those most at risk will be plant operators although a catastrophic failure of a lagoon wall could lead to serious damage outside the boundary of the mine. Access of the public to wet areas should be included in the risk assessment.

Preventative measures to reduce the risk of accidents include the working of the mine so that the winning does not undermine the stability of equipment. The provision of suitable and adequate fencing around the water laden area, the provision of suitable buoyancy aids for person’s working on the lagoons and proper design, planning and building of waste tips where water could affect it and stability of lagoon walls etc. Lagoon walls and tips should be regularly examined by competent persons to establish that there is no danger of failure which could lead to a slide or collapse.

Ornamental stone quarries

Ornamental stone quarrying produces blocks of marble and other ornamental stones for subsequent sawing. The main safety problems involved arise from primary block extraction. Most accidents are associated with the specific operations to separate the primary blocks from the rock ledge, toppling, subdividing the blocks at the quarry, and movement of the materials and equipment.

Initial separation and subdivision into mill blocks can be carried out using automatic drills, chain cutters or wire sawing with diamond or helicoidal wire, depending on the nature of the stone to be extracted and the operational choices made.

The current trend is towards greater use of equipment with wires moving at high speed, to allow greater square footage to be cut per unit of time.

Primary block extraction

As a preventive measure, trained workers must wash the block if necessary and check it for stability and flaws, depending on how it is to be cut. The shape of the block to be separated must be properly outlined.

When helicoidal wire saws are used, the wire must be arranged in the most suitable manner in order to safeguard workers near the sawing operation. In particular, guards must be in place while the wire is moving and precautions taken in case it breaks.

When cutting is performed with a diamond wire saw, the tracks must be placed on well-levelled ground. Wear of the flywheel tread must always be checked so that no work has to be done once cutting has started.

The greatest risk to workers from diamond wire cutting arises from high-velocity projection of the beads if the wire breaks. Safeguards must therefore be provided for the cutting operation and the quarry in general.

The machine’s control panel must be placed to one side of the cut plane and at an adequate distance, depending on the height of the cut. If several cutting operations are carried out on the same bench or quarry floor, the machines must be so positioned that the workers cannot be endangered by flying beads if the wire should break. If a mechanical cutter is used, it must be properly positioned to ensure machine stability and operator safety.

Subdivision into mill blocks and squaring

The cutting phase of this operation involves the same risks as primary block extraction and the same precautions must therefore be taken to ensure workers’ safety.

Block toppling

Blocks which have been separated from the rock ledge may be toppled by means of inflatable bags, hydraulic jacks, hauling with ropes using a winch or bucket loader, direct pushing with a loader or tilting with an excavator.

The main risk is that the workers involved may be crushed if the operation miscarries because the bearing surface is unstable or the block or traction equipment fails. Flying fragments may result from plant operation or the impact of the block striking the ground.

On-site block handling

The purpose of handling blocks in the quarry is to position them for subdivision and squaring, to store them in suitably prepared areas and to load the trucks for transport to the processing mill.

The material is moved with derricks or bucket loaders, which must be regularly maintained to keep them in good working order. It is particularly important to safety for the dimensions and surfaces of haul roads, benches and quarry floors to satisfy the operational requirements of the plant.